Zündapp provided its dealer network with bespoke tools for their various models at manufacturing cost price. Frequently such tools are indispensable if you want to quickly, easily and more importantly without damage work on a bike on scooter.

This section below looks at some of the tools provided by Zündapp, what they do and whether there are alternatives.

2501 k 24-3 = ZWN 315 – Hook Wrench

This wrench is specifically made for installing and removing the exhaust pipe nut on some models. It is not needed for the Zündapp Bella, so I have not looked into alternatives.

2021 z 51 – Socket Wrench

This is a square socket wrench that can be used for the cylinder head screws as well as the wheels. I ordered one from Helmut and Iris Bougé.

2500 k 5 – 2 = ZWN 788 – Socket Wrench

2500 k 6 – 2 = ZWN 789 – Socket Wrench

This pair of socket wrenches can be used to adjust the steering column locking nuts of the Bella with the handlebar removed, but everything else in place (so without removing the headlight cover).

I will attempt to recreate the tool here:

http://noxxou.synology.me/bella/?page_id=1636

2501 k 12-0 = ZWN 212 – Konck-out puller

This puller is used for forcing out the gudgeon pun in the piston.

2501 k 63-0 = ZWN 738 – Gauging Pin

The pin in coneetion with a gauging ring are used for trueing the connecting rod.

2501 k 47-2 = ZWN 452 – Squeezing screw

Instead of the set screw, the squeezing screw is screwed into the armature of the generator until the armature is loosened. Regarding scooters with electric starter, the screw has to be shortened by 10 mm.

As far as I can tell the screw consists of an M10 bolt where the bottom part is milled down to 8 mm. The thread engages the generator and the bottom part of the bolt then pushes on the axle. I’ve ordered a BMW bolt that appears very similar. To be continued.

2500 k 2-0 = ZWN 392 E – Graduated Disc with Bolt

After having removed the armature fixing bolt, turn into the armature thread the disc fixing screw (M10 x 25), tightening it by means of the lock nut. The disc is used to set the ignition timing.

2501 k 10-2 = ZWN 208 – Socket wrench 10 mm and plug in screwdriver blade

This is your bog standard T-bar handle with 10mm screwdriver bit to unscrew the bolts in the engine housing. An impact driver can be used too for stubborn bolts.

2501 k 72-2 = ZWN 783 – Knock-out pin for cotter pin

Works for the gearshift fork, gearshift pedal, kickstarter). This tool is a punch with M6 thread in the bottom to the punch can be screwed onto the cotter pin to hammer it out. This prevents damaging the thread on the pin. This does not work perfectly for cotter pins that are very tight; a cotter pin press can be used instead.

2501 k 66-2 = ZWN 777 – Socket wrench 32mm

This is a bog-standard box spanner of 32 mm used to take off the flywheel nut.

2501 k 74-0 = ZWN 785 = Flywheel puller

The puller serves for pulling off the flywheel. It comes with 3 hex screws M8x50 DIN 931. By screwing these in the flywheel is removed.

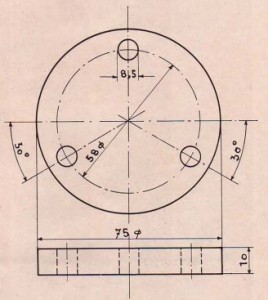

This tool is a circular disk of 75mm with three equidistant holes 58mm from the center:

I’ve ordered a standard harmonic puller to try and do the same.

2500 k 10-0 = ZWN 786 – Clamping screw

The clamping screw is used to fix the clutch plates in place so the entire assembly can be taken off and put back on. This is necessary as the clutch assembly and the flywheel need to be mounted at the same time.

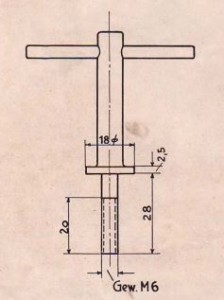

The screw consists of an M6 bolt with 20mm thread and 8mm unthreaded bolt. Instead of a hex head a T-bar handle is fitted. An M6x30 hex head bolt with a washer will do the same. Should you want to create the proper tool, this is the design:

2501 k 71-2 = ZWN 782 – Tension bolts

Three tention bolts are symmetrically screwed into the clutch and tightened in order to counteract spring pressure exerted onto the discs (e.g. when removing the assembly or the ring holding the assembly in place.

The bolts consist of a 10 mm round top of 20mm, followed by 25mm of M6 thread. I’ve ordered M6x45 allen head bolts. The heads are 10mm in width so a perfect match. A 20mm M6x10 screwed bushing (standard order) can be screwed onto the bolt to create the 20mm round head (plus the head of the allan screw extra; I couldn’t find a 15 mm standard order bushing, but the length is not that relevant for what it does) and the 20mm thread. The only difference is the allen head compared to a cheese head in the original; this will last longer. I locked the bushings using loctite.